Description

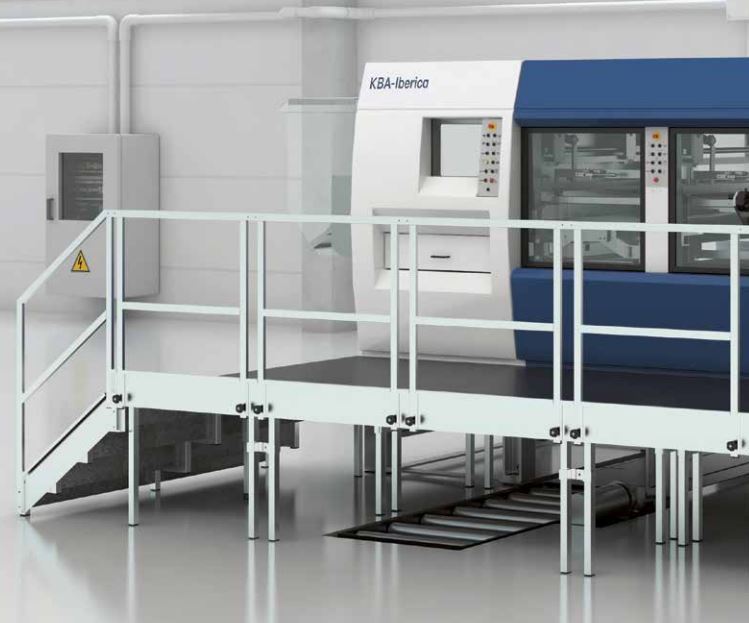

Koenig & Bauer Optima 106 K

Flatbed Die-Cutters

- The versatility of the Optima Series gives the possibility to die-cut several types of substrate including paper, plastic, board and corrugated material.

- The comprehensive range of optional equipment allows the configuration of the “perfect” Die-Cutter giving our customers the ideal machine for all of their requirements in the Packaging Industry.

- Its 100% manufacture process made only in our plant in Barcelona makes the Optima Series the perfect investment for those who look for high productivity and long-life of machinery.

Product Info

The Koenig & Bauer Iberica Optima Series is our basic Automatic Platen Press. Launched in 2008, we proudly announce that the Optima Series have today it’s version in a new format 106.

With its “operator friendly” innovations and ease of handling, this model maintains Iberica’s quality of build and performance the combination of which generates a significant increase in productivity.

- The versatility of the Optima Series gives the possibility to die-cut several types of substrate including paper, plastic, board and corrugated material.

- The comprehensive range of optional equipment allows the configuration of the “perfect” Die-Cutter giving our customers the ideal machine for all of their requirements in the Packaging Industry.

- Its 100% manufacture process made only in our plant in Barcelona makes the Optima Series the perfect investment for those who look for high productivity and long-life of machinery.

- The new blanker Optima 106 K is the perfect tool for customer who enters in the blanking world, due its high quality, high productivity, easy handle and fast preparation as well as for an interesting price range.

- This new generation of Koenig & Bauer Iberica blankers is equipped with new tooling technology to do “sheeting” in a fast and easy way. This is the result of the synergy and collaboration with local die-makers, for the continuous improvement of our units.

Features

- Automatic feeder head designed for quick and easy preparation comfortably handles a wide range of materials. In conjunction with incorporated automatic pile displacement, perfect feeding of sheets is achieved.

- Manual non-stop feeder for continuous production.

- Machine elevated giving the possibility to work with higher piles. (Maximum pile height in feeder = 1690mm. Maximum pile height in delivery = 1400mm.)

- Feed table made from anti-static stainless steel. Equipped with variable speed belts which have individual tensioners and ensure perfect arrival of the sheet at the front lays.

- Two adjustable side-guides for all formats, with dual function pull and also push facility which is employed when working with micro-flute or corrugated material. New inductive front-lay system for perfect register of sheet regardless of material type, grammage, colour and other characteristics of the sheet. Comprised of four motorised front-lays controlled through the touch screen.

- Latest generation of die-cutters designed and equipped with the VARIOPLAN®SYSTEM of Koenig & Bauer Iberica. The presses are adjusted by hand at our Barcelona plant and built using the best European materials guaranteeing our customers long life and maximum strength for their die-cutter. The 300 tonnes (330 US tonnes) of punching pressure makes the Koenig & Bauer Iberica Die Cutters unique in its sector.

- The Optima series is equipped with an operator friendly touch screen giving complete control of all sections of the press. A remote connection IP system allows us to offer immediate assistance.

- An optional pneumatic locking system in the chase (Fast Flow®) for perfect positioning of the cutting forme and a reduction in make-ready time.

- Machine equipped with upper Quick-Lock System stripping and blanking frames for use with dedicated tooling.

- Machine equipped with standard upper and lower stripping frames with complete set of accessories for use in manual setting of the unit or in the (optional) Pre Make Ready table.

- Machine equipped with a lower blanking frame and universal tools for use in manual setting of the unit or in the (optional) Pre Make Ready table.

- Machine equipped with special “ImpulsBCN®” tool for the quick and easy preparation of upper blanking when “sheeting.” This innovative system has been developed thanks to the co-operation between BCN Troqueles www.bcntroqueles.es and Koenig & Bauer Iberica that will give both companies the possibility to grow and improve continuously for the benefit of our customers.

- Automatic changing of the pallet in combination with a non-stop interleaving system gives stability to the delivered pile. Settings for this facility are carried out through the touch screen. These settings can be stored in the memory giving a reduction in make-ready time with repeated work.

- Dynamic waste removal system ensures the perfect ejection of waste.

Options

- Platform with “chase-changer” for customers who are looking for flexibility and speed in the preparation of the following job.

- Anti-static kit for feeder head and feed table giving improved performance when die-cutting plastic materials.

- Heavy duty transport wheels for perfect feeding of the sheet on the feed table, specially designed to work with corrugated board.

- One Pre Make Ready table for stripping and blanking allowing us to prepare the next job whilst the machine is in production.

- Include One standard upper stripping frame with a complete set of accessories.

- Include One standard lower stripping frame with a complete set of accessories.

- Include One standard lower blanking frame with universal tools.