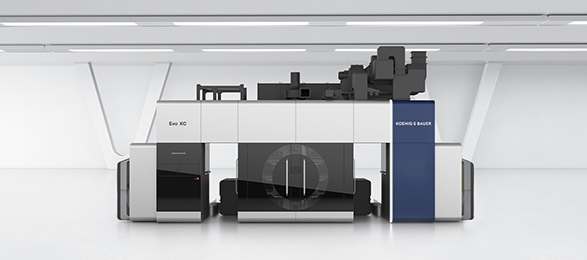

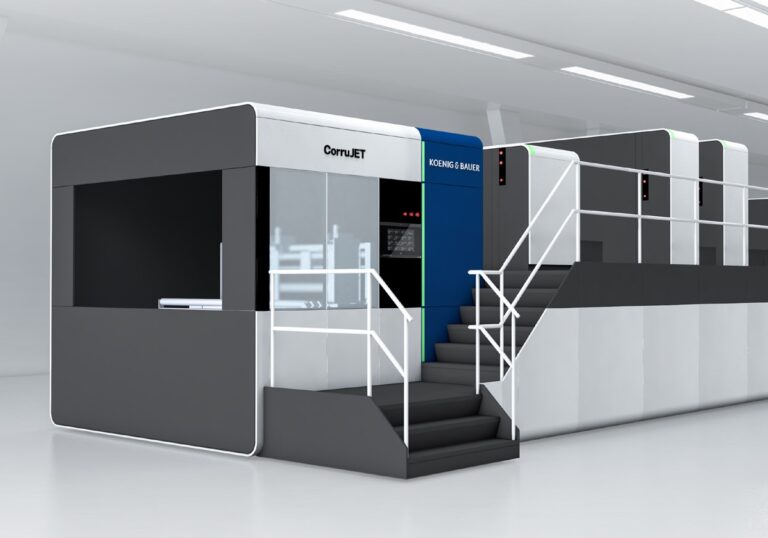

Digital post-printing

- Modular design for four colours

- Water-based, food aproved inkjet inks

- Fuji Dimatix Samba printing heads with variable drop size

- Inline Pre-coater and Post-coater

- Press control via a flexible Profibus system with touchscreen interface