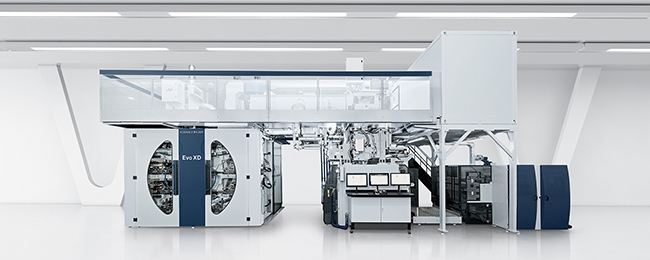

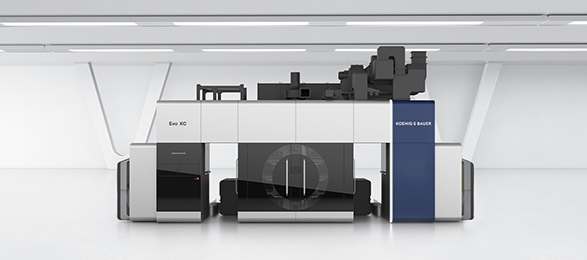

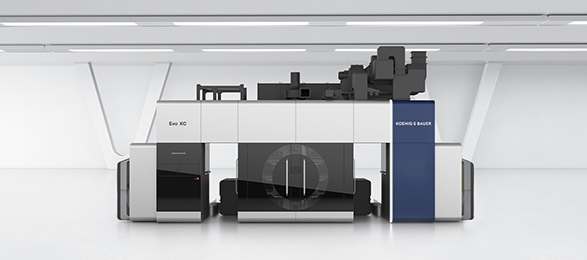

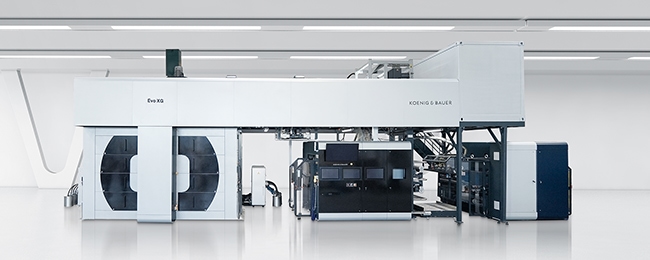

CI Flexo Press

- Small space requirement and outstanding print quality

- User-oriented machine design with intuitive operator interfaces

- Performance-enhancing, fast job changeover

- Low investment costs combined with sustainable energy-saving package

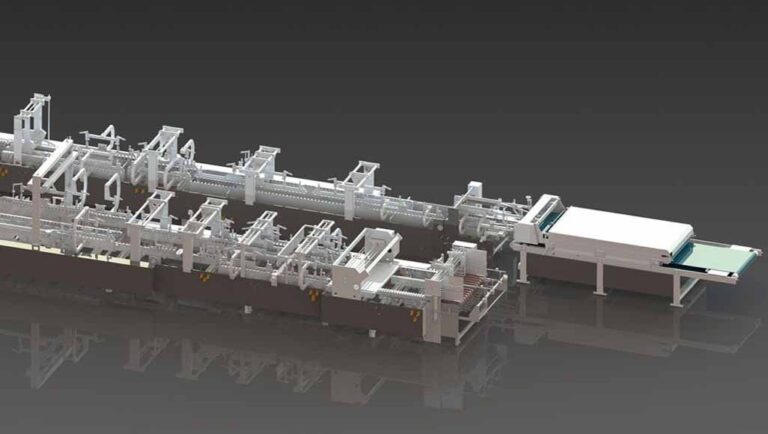

Omega Carton Bag Machine 145 is a revolutionary folder gluer designed especially for carton makers operating with standard printers and die-cutters for getting into the carton carrier bag business with only the Omega Carton Bag Machine investment, as well as specialist companies producing luxury carton carrier bags with manual operations.